Smoother Ballast Water Operations on All the World’s Oceans

Optimarin provides smart systems for treating ballast water on ships. This fall, they began a collaboration with Digitread Connect to develop applications that display valuable data for shipping companies. The goal is to provide shipowners with better insights and make ballast water operations even more efficient and streamlined.

"One of the things we like most about Digitread Connect is their working approach. They asked us what a minimum viable solution would entail. Then, they developed a solution that worked in the real world within a week and a half. After that, we continued to work in short sprints where they developed specific, limited improvements, making the process clear.

The advantage is that we quickly reach each milestone, and it’s easy to adjust the course if anything needs to be changed along the way. This collaborative approach has therefore suited us very well and provides us with increasingly better functionality," explains Ingve Risa, System Engineer at Optimarin.

Ingve Risa is a System Engineer at Optimarin

Ballast Water as an Environmental Challenge

All cargo ships pump ballast water in and out of their ballast tanks to keep the vessel stable. However, the issue is that ballast water pumped into the ship in one location carries organisms that can impact ecosystems when the ballast water is discharged—often in seas on the other side of the globe. For example, the English Channel has become home to species that don’t belong there, and Canadian lobsters have been recorded in southern Norway.

But there are many more examples, and since this is one of the significant maritime environmental challenges facing the world, strict regulations have been introduced for treating ballast water on ships. New regulations now in force require that all ships in commercial traffic must have a treatment system installed by 2025 at the latest.

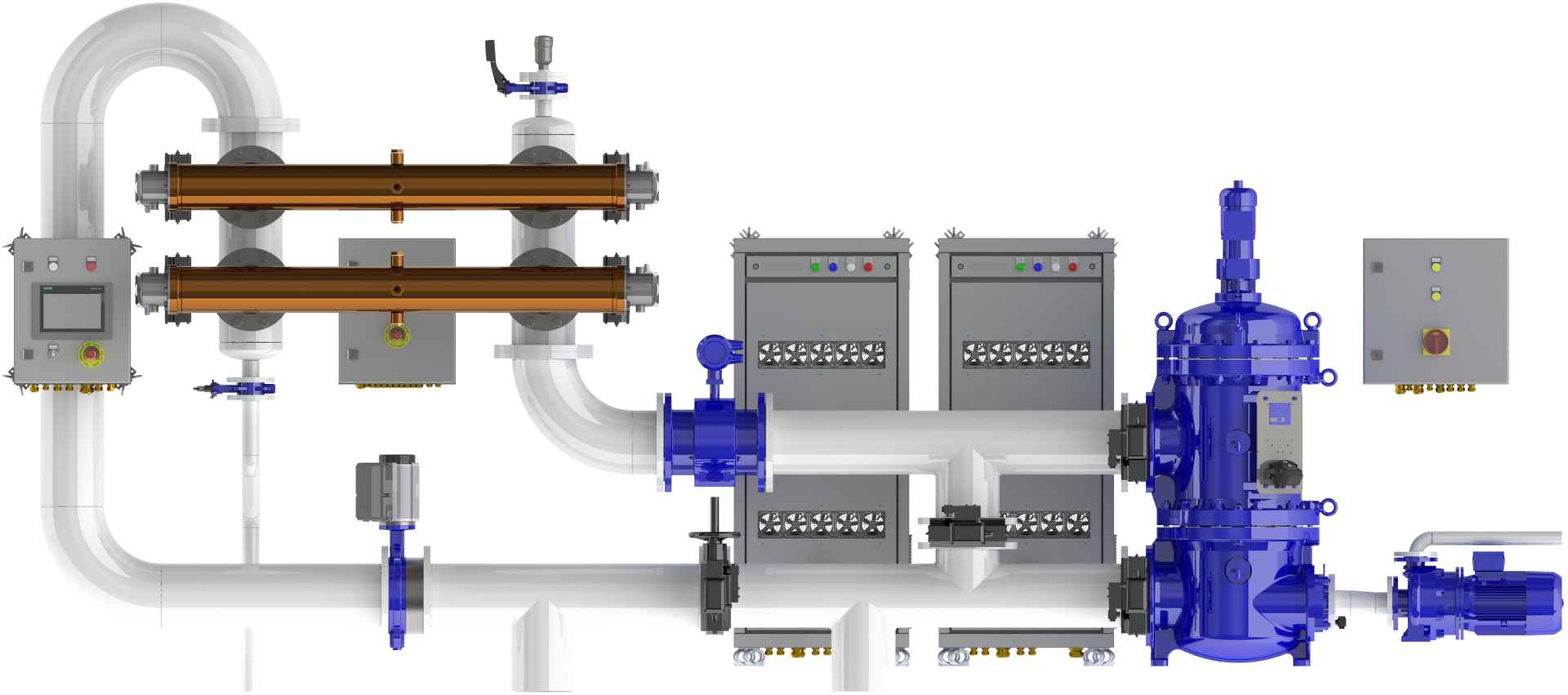

Filtration and UV Light

Optimarin has developed a treatment solution approved for use in all the world's oceans. The process consists of two steps: first, a particle filter stops larger organisms and particles, and then the water is irradiated with UV light. The light ensures that the remaining particles either die or become sterile, preventing them from reproducing.

The system is modular and can be scaled to treat from 87 to 3,000 cubic meters of ballast water per hour. The modules are placed between the pumps and ballast tanks on ships and contain filters, a UV module, sensors, as well as control, monitoring, and analysis systems.

Quick and Efficient

"Digitread Connect has the expertise we lack and was therefore exactly the partner we were looking for. We were also shown solution examples, which made it much easier for us to understand what was possible and to decide what services we could offer in addition to what we currently provide," continues Risa.

"We needed someone who knows how to efficiently retrieve data from the cloud and could deliver user-friendly and tailored Optimarin applications as ‘software as a service.’ It was also important for us to find someone who could do this quickly and efficiently. Digitread Connect has proven they can," he adds.

The applications are built on the Norwegian Appfarm low-code platform.

A Tool for Shipowners to Save Money

"Since we work in sprints, we can develop the system in small steps, which means we don’t invest the entire budget on a single solution that may not reach completion at all. Instead, we have a flexible development pathway that allows us to adapt the solution as new needs and opportunities emerge," Risa explains.

The first pilot was tested on a ship in November and involved a digital solution where data is displayed in real-time without any manual intervention from the moment it’s generated to when it’s presented on a user-friendly interface. By collecting health data on the onboard treatment system and presenting it to the shipping companies, it becomes easier to conduct preventive maintenance in a more structured way. But many new possibilities are also emerging:

"It’s faster to treat clean water than murky water, and the cleaner the water, the less energy is required for UV treatment. As we gather more data on water quality in the world’s ports, we will soon be able to provide shipping companies with information about the water quality they’ll encounter at their next port, making it easier for them to plan their operations.

We may also be able to link this information with exact GPS data so that shipowners, for example, can move their vessels a few hundred meters to find areas where the water is as clean as possible. Now we have the most important infrastructure in place, and we can continue to develop more solutions like these that will simplify the day-to-day operations for shipowners and help them save money by using our solutions," concludes Risa.